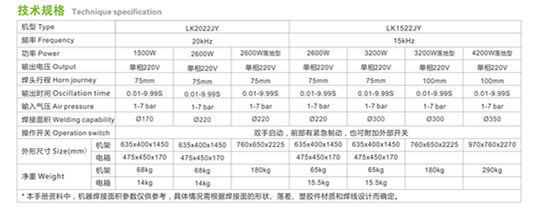

Technical parameters of ultrasonic plastic welding machine:

Working principle of ultrasonic plastic welding machine:

The 50/60hz current is converted into 15, 20 and 35 thousand HZ electric energy by ultrasonic welding machine. High frequency electric energy of converted by ultrasonic transducer again converted into mechanical movement of the same frequency, then through a set of mechanical movement can change amplitude modulator device is passed to the ultrasonic welding head. The ultrasonic vibration energy received by the welding head is transferred to the joint part of the welder. In this area, ultrasonic vibration energy is converted into heat by friction and melts the plastic. The welding time of ultrasonic plastic welding machine and welding head pressure can be adjusted, and the amplitude is determined by transducer and swing lever.

Application field of ultrasonic plastic welding machine:

Ultrasonic welding (i.e., seamless welding sealing and sealing) : Ultrasonic vibration with ultrasonic welding dies, the ultrasonic energy is transmitted to the plastic surface welding, resulting in local high temperature, the plastic surface melting. Under the pressure of ultrasonic welding machine, two pieces of plastic can be welded, beautiful and strong. Ultrasonic embedding Insert the nut screws or other metal into the plastic workpiece. The ultrasonic energy is transmitted to the metal by the ultrasonic machine. After high - speed vibration, the metal is embedded into the plastic under the pressure of the ultrasonic machine. Ultrasonic riveting The metal and plastic or two different kinds of plastic joint, can be used ultrasonic machine riveting method, make the welding piece not easy to embrittlement, beautiful, strong. Ultrasonic spot welding Using the small welding head of ultrasonic machine, two pieces of plastic products are divided into multi-point welding, or the welding head of the whole row of teeth is directly pressed on two pieces of plastic workpiece, thus achieving the effect of ultrasonic spot welding. Ultrasonic forming Use the ultrasonic machine to melt the plastic parts in an instant. When the plastic solidifies, the metal or other materials can be made of solid plastic. Ultrasonic removal The special design method of ultrasonic welding die and bottom is used to achieve the effect of ultrasonic removal of cloth or plastic by ultrasonic conduction.

Application situation of ultrasonic plastic welding machine:

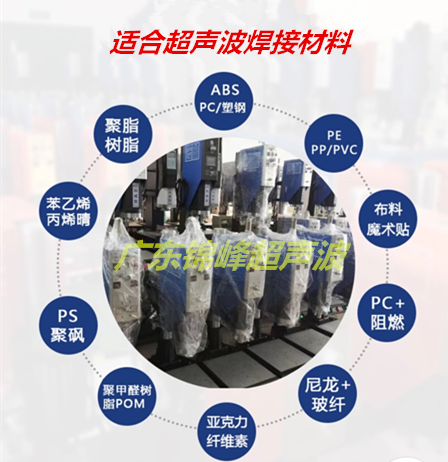

Apply toAviation, ships, automobiles, electrical appliances, packaging, toys, electronics, medical equipment, packaging, auto parts, fishing gear, textile.Etc,Such as disposable transfusion plasma separation filter and cup, hydraulic valve bag, plastic JiuPingGai, dishwasher, plastic toys, car lights, plastic false bait, the welding of the charger shell and cell phone strap, a lighter shell welding, etc.Welding, such as: car door auto meter welding, headlights, car mirror, sun visor, interior parts, welding, welding filter, reflective material welding, reflective spike, bumper welding, welding, motorcycle lasso plastic filter welding, radiator, brake fluid tank welding, welding oil cup duct tank, water tank welding, ultrasonic welding, ultrasonic welding, exhaust gas purifier filter plate ultrasonic welding, ultrasonic welding, tray water welding table electric meter ultrasonic welding, communications equipment, cordless electric welding words, mobile phone accessories welding, following welding, battery shell, charger welding, U disk, SD card welding, CF card, USB socket welding welding, bluetooth, folder, album, welding, welding folding box, PP hollow plate welding, the cap welding, welding, toner cartridge drum welding, welding, watches, kitchen utensils and welding, oral liquid bottle cap welding, intravenous drip cap welding, mobile phone accessories, soft brush welding of gold daily necessities welding, health supplies welding, children's products welding, welding, air mattress hangers welding, welding hilt, gardening supplies welding, welding, clean of kitchen utensils, flower is aspersed welding shower head welding, anti-fake bottle cap welding, cosmetics bottle cap welding, welding, coffee pot washing machine welding, air dehumidifier, welding, electric kettle, electric iron welding, vacuum cleaners, speakers civil grille welding metal surface welding, etc.Applicable plastic material for ultrasonic plastic welder: